|

Musclecar Restoration and Design, Inc. prides itself in doing only

the best, highest quality restorations available. Our motto is “Details

Make the Difference” and we prove that every day leaving nothing

too small undone. Over the years we have developed systems and techniques

for plating and sealing suspension components and the correct “fish

eye” trunk spatter paint as examples that continue to excel us above

the rest. We restore cars for the collectors and not the people who

just want to turn their cars around and sell them. Because of this our

cars are restored just as precise in the areas that cannot be seen as

the ones that can be unlike cars only restored so they can be turned

around and sold which are usually only cosmetically restored. |

|

|

|

|

The bodies are painted just as they were originally

at the Fisher Body and the assembly plants with regards to paint

overspray, thin paint areas, paint drips/runs on the firewall

and belly pan, etc. However, panel fit and finish go way beyond

the factory’s as their tolerances were way too great compared

to today.

Areas such as the inside of the trunk lid, door hinge area,

front fender apron, taillight panel, etc. all had thin paint

on them originally which is replicated during the restoration.

Techniques vary between plants and this is also taken

into consideration especially in areas of the floor pan where

some plants left them primed while others painted them black.

In either case body color overspray would be evident. All spot

welds and factory metal stamping stretch marks are replicated.

We prime our cars in the same color primer as the factory used

at that particular plant be it grey, red oxide, rosette or black.

These are also applied the same way the individual factory did

them. |

| |

|

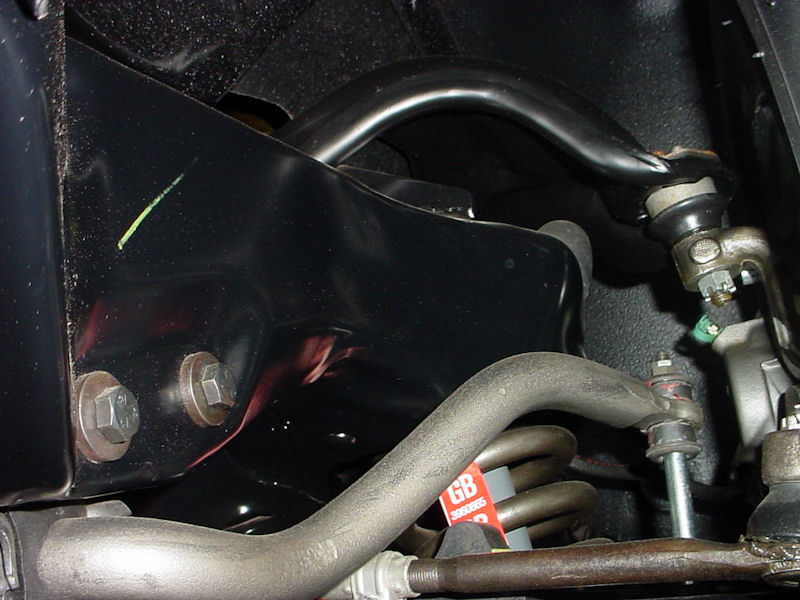

Many years ago we developed a system to plate

and treat suspension pieces. These items were never painted

originally from the assembly plant and we don’t paint ours either.

Many of these items were heat treated steel or cast iron and

therefore will have a different look then non-heat treated bare

cast items.

Note in the photos the plating and treatment applied as well

as the original inspection marks that were put on by the manufacturer

prior to assembly. Some of detail to note in the following photos,

brake bleeder dust covers, heat treated suspension pieces, inspection

marks, rubber mold release on rubber parts, correct dull and/or

bright zinc plating, correct cadmium plating, riveted ball joints,

exact decals and stamps made from originals, tire stamps, wheel

well undercoating, etc. |

|

|

|

|

|

| |

|

|

Unlike most shops that use silver paint, we

also will either chrome plate or chrome paint your dashes where

applicable. At a glance they look exactly the same and cost

about the same with the chrome plating process being a little

more. Once the dash is chromed it then receives the correct

color paint. All gauges are checked and rebuilt as needed. Clocks

are rebuilt using the latest quartz internals. |

| |

|

|

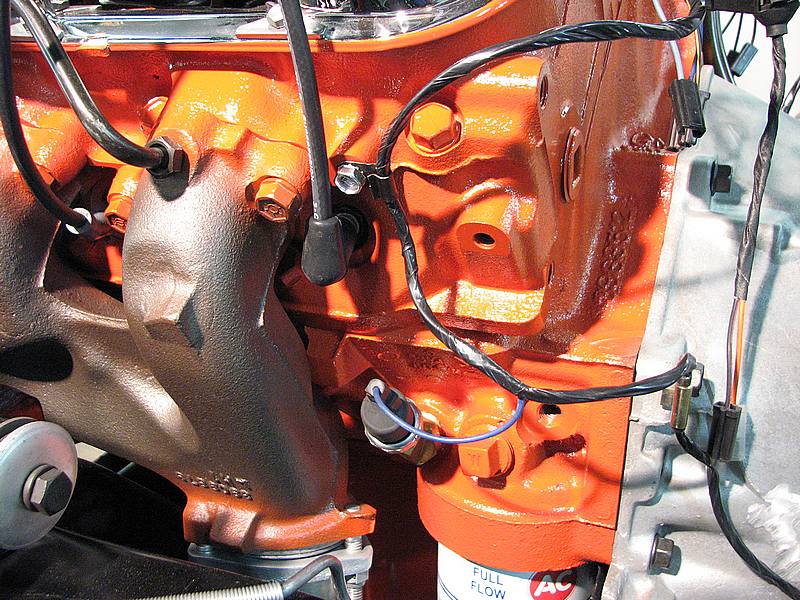

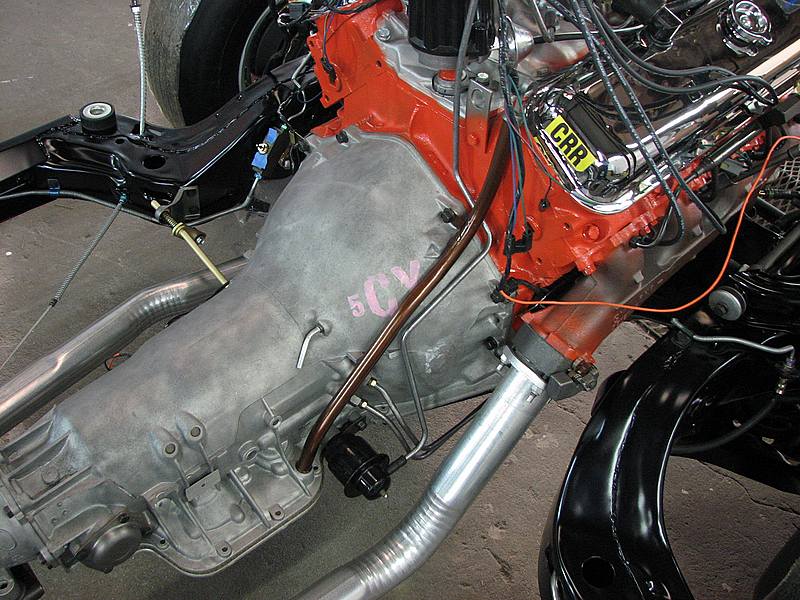

In these photos you can see the attention to

detail that goes into the engine and transmission assemblies.

The engines are restored to an appearance just as they were

originally assembled and painted at the Tonawanda engine plant

per the customers request. All paint codes, inspection marks,

paint dabs, etc. are replaced on the block just as they originally

were. The engine is sprayed with enamel paint and over sprayed

just how they were done on the assembly line with overspray

on the valve covers, intake, exhaust, etc. Masking tape is applied

to areas that were originally masked off such as water pump

snout, fuel filter area, VIN and code stamp area, etc.

|

|

|

|

|

|

| |

|

|

We have reproduced for our use most all the

decals and stamps found on these engines such as carburetor,

PCV hose, radiator hoses, smog hose, fuel line hoses, transmission

codes, alternator, etc. Each engine is researched to see what

stamps and inspection marks were used on them and then painstakingly

reproduced. The firewall is no exception. It receives most of

its grease pencil codes prior to primer and paint and is allowed

to bleed through just like the originals. Some codes are applied

on top of the firewall paint as well. Most of our decals have

been duplicated by a Graphics Art Designer and are exact copies

of the originals. There are many variations of these decals

depending on vendor and we have tried to cover most all of them.

|

|

|

|

|

|

| |

|

|

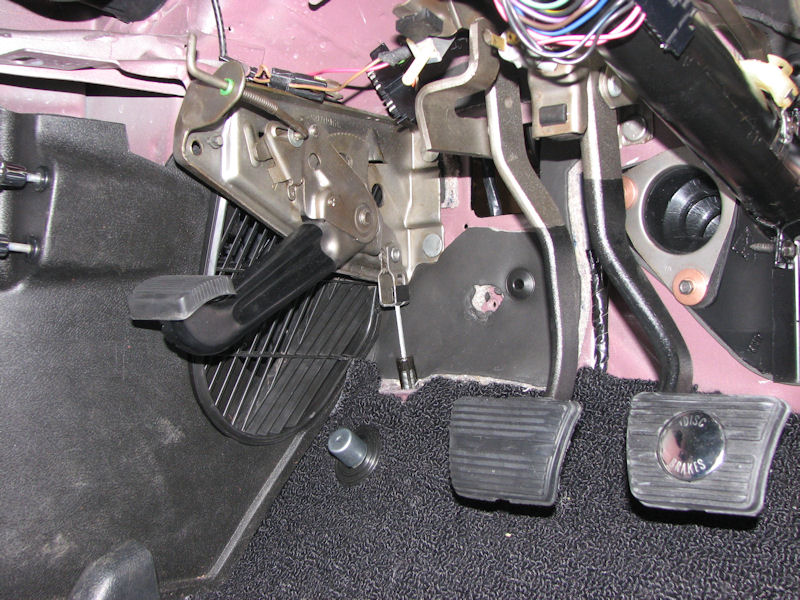

The Interior receives just as much attention

as the rest of the car. Many people ask me why I restore the

interior to this degree when it cannot be seen. My answer is

simple, if I put this much attention to detail in an area that

cannot be seen, imagine what attention it gets to areas that

can be seen. All sealers are replicated as is the use of any

tapes, clips, etc. to hold harnesses in during assembly. Caulking

and sealers are applied just as the factory did. They are also

applied in the order that the factory did them with regards

to what got painted, primed or just over sprayed. Even our carpets

are cut exactly as the originals depending on bench or bucket

seats as well as the frames mounted to the floor through correctly

slotted carpet cuts.

|

|

|

|

|

|

| |

|

|

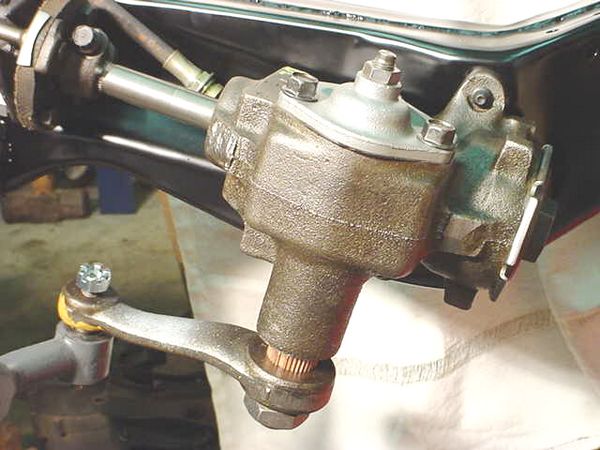

Every component gets rebuilt and restored such

as power brake booster, windshield washer motor, steering gear,

brakes, suspension, rear end, bushings, all thing mechanical.

All receive the same amount of attention and detail as the rest

of the car.

|

|

|

|

|

|